burst strength test corrugated|5 ply corrugated box burst : export Often called the Mullen Burst Test, burst strength is an industry standard that measures the amount of force required to burst corrugated boxes and flexible packaging.

Hero RC H911 iRocket 4 Channel Fixed Pitch Ready to Fly H.

{plog:ftitle_list}

Resultado da 6 de abr. de 2020 · Edit | Report. Want to watch the anime Ore no Yubi de Midarero.: Heitengo Futarikiri no Salon de. (Crazy Over His Fingers)? .

When determining the strength of a box, the corrugated box industry uses two test, the Bursting (Mullen) Strength Test and the Edge Crush Test (ECT). The Bursting Test is reported in pounds and is related to the handling durability of the box material.This document provides general material and functional requirements for corrugated boxes used for inbound, interplant, and outbound nonbulk shipments. The boxes described herein are .

The bursting strength of a corrugated sheet can be easily calculated by performing the bursting strength test or the Mullen test. This is .Until 1991, the only method available for measuring the strength of corrugated was the Mullen Test, (also known as the Bursting Test). The Mullen Test, which is still used, is a good way to determine how well corrugated packaging can .The ECT is a burst strength test that measures corrugated boxes' stacking strength. As the name suggests, it's the force required in psi to crush cardboard by standing it on its edges. It measures compression strength from top to .

Often called the Mullen Burst Test, burst strength is an industry standard that measures the amount of force required to burst corrugated boxes and flexible packaging. Learn about the history of corrugated strength testing and the two standard test in the industry: the Mullen burst test, and the edge crush test or ECT.

The burst test is frequently used as a general guide to the strength of paper, solid board and corrugated board. Bursting strength is usually quoted in kPa. We determine bursting strength using a digital hydraulic paper or digital .

This test, also known as a Mullen Burst Test, is one of the most common material properties test required by carriers and governments. Bursting Strength testing basically measures the force required to puncture through a .The measurement of this parameter is particularly important for materials that will be subject to high pressures, such as packaging applications. The Bursting Strength Tester can be used to measure bursting strength of both flat and .The burst test determines the maximum resistance (in kPa) of a specimen to an increasing pressure. ZwickRoell burst testers determine the bursting strength of paper in accordance with ISO 2758.The bursting strength of board and paper to ISO 2759 can also be determined with ZwickRoell, thereby covering the entire range from paper to heavy corrugated board.

A: The Mullen Test measures the burst strength of corrugated board by determining how much pressure is required to puncture the face of corrugated material. In contrast, the ECT measures the edge compressive strength perpendicular to the direction of the flutes, which is crucial for understanding a box’s stacking strength.

The ECT is a burst strength test that measures corrugated boxes' stacking strength. As the name suggests, it's the force required in psi to crush cardboard by standing it on its edges. It measures compression strength from top to bottom. For example, a box with a 32 psi ECT result implies that the parcel can bear a force of 32 psi before crushing.Further experimental studies involved the construction of rigs for testing corrugated board panels under compression and cylinders under combined stresses. The panel test rig, furnishing simply supported boundary conditions on all edges, was used to . the top-to-bottom compressive strength of corrugated containers has been used as the basic .Mullen Test (Burst Test) for Box Strength. The Mullen Test (burst test) has been used for over 130 years to determine how resistant a box is to punctures. These days punctures from outside sources are a very prominent threat during transit when a box is moved. . If a corrugated container has a 55 ECT rating, it means that it can withstand a .Get quotation from a top manufacturer and supplier of bursting strength tester / BS testing machine. +91 9313 140 140 . . Bursting Strength Tester digital model is a very accurate instrument for the measurement of bursting strength of corrugated boxes and paper by manufacturers and suppliers. It has a two in one feature of calculating .

There are a number of different ways to test the bursting strength of a corrugated box, but the most common method is the Mullen test or bursting strength test.This can be performed with the help of the Presto bursting strength tester digital model that comes with feather touch controls and strong gripping clamps to accurately place the machine on the surface.

The TAPPI T810 Burst Test of Corrugated Board is a standard test method used to determine the bursting strength of corrugated board. This test is commonly used in the paper and packaging industry to evaluate the performance of corrugated board materials and to ensure they meet specific quality standards.The Mullen Test, also referred to as the Mullen Burst Test or Burst Strength Test, is a standard test used to evaluate corrugated board’s resistance to puncturing or bursting. It measures the amount of force, in pounds per square inch (PSI), required to rupture the face of the board using pressure and a Mullen tester.Bursting strength is reported in pounds (for example, 275#). A newer standard that has achieved widespread acceptance is the Edge Crush Test (ECT). This is a true performance test and is directly related to the stacking strength of a carton. ECT is a measure of the edgewise compressive strength of corrugated board. It is measured by compressing .

All components of solid and corrugated fibreboard, irrespective of bursting strength, should be tested . the test piece ruptures. The bursting strength of the test piece is the maximum value of the applied hydraulic pressure. 5 Apparatus The apparatus shall contain, as a minimum, the features described in 5.1 to 5.4. .

Board — Determination of bursting strength 1 Scope This International Standard specifies a method for measuring the bursting strength of board submitted to increasing hydraulic pressure. It is applicable to all types of board (including corrugated and solid fibreboard) having bursting strengths within the range 350 kPa to 5 500 kPa.

Determination of bursting strength This International Standard specifies a method for measuring the bursting strength ofboard submitted to increasing hydraulic pressure. It is applicable to all types of board (including corrugated and solid fibreboard) having bursting strengths Within the range 350 kPa to 5 500 kPa. It is also applicable toBursting strength or burst resistance is a property of a plastic, paper or corrugated board -used in packaging- and is general a guide to the strenght of that plastic, paper or corrugated board. Mullen Test A Mullen (bursting) test .There are currently two tests used throughout the corrugated industry to determine strength. Historically, the long time industry standard has been the Bursting (Mullen) Test, which is related to the rough handling durability of corrugated material. Bursting Test is a measure of the force required to rupture or puncture the face of corrugated

Edge Crush Testing . A newer standard that has achieved widespread acceptance is the Edge Crush Test (ECT). This is a true performance test and is directly related to the stacking strength of a carton. ECT is a measure of the edgewise compressive strength of corrugated board.The burst strength test consists of an assessment of the protective capacity of corrugated board, in particular to prevent cases of incorrect and rough handling. In this case, the force required to puncture or break the face of a corrugated board is measured. . TAPPI T810: Bursting strength of corrugated board Procedure for measuring the tear .The TAPPI T 810 Bursting strength test describes a procedure for measuring the bursting strength of single wall and double wall corrugated board. . The minimum bursting strength of corrugated board is a requirement of various carrier and governmental specified regulations for shipping containers. While bursting strength is an empirical .

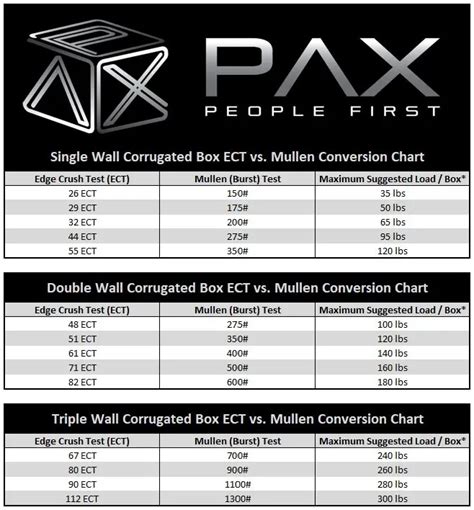

Corrugated material is measured by several factors, including bursting test, edge crush test, combined weight of material, maximum weight of contents, and outer dimensions. Here is a handy chart to compare all of these variables. Please contact Pro Pac or call 888-318-0083 for your corrugated shipping cases. Minimum Bursting Test (lbs per sq. inch/kg per sq. cm) Minimum Edge Crush Test (ECT) (lbs per inch/kg per cm width) 5-10* 30* 125 * 23* 30 75 200 32 40 75 200 40 50 85 . For added strength, corrugated sheets can also be double- or triple-wall. eCommerce shipping boxes are generally made with single-wall B, C, or E flutes, all striking an .certification called ECT or Edge Crush Test. The ECT method was developed to provide a way to determine the “strength” of a corrugated box as it relates to stacking, or Box Compression strength (also referred to as BCT or Box Compression Test strength). ECT is a more appropriate measure than Burst when stacking strength is a primary design .

mullen vs ect conversion chart

BT-21 Burst Strength Tester: The BT-21 Burst Strength Tester can ascertain the critical components of the corrugated board such as bursting strength, burst index and absolute strength. RL-BT-A (Paper and Paperboard): The Rycolab RL-BT-A Burst Tester measures the bursting strength of paper and paperboard using the MULLEN method.

Thus, by measuring the bursting strength of corrugated boxes it is easy for you to deliver quality products to the customers. Presto has come up with one of the amazing lab testing equipment known as a bursting strength tester, that will help you to evaluate the bursting strength of corrugated boxes.Top 3 challenges faced by manufacturers while conducting bursting strength test The Presto Digital Bursting Strength Tester is used to determine the bursting strength of paper and paper-board by applying a progressively uniform hydraulic pressure to it. Preparing the specimen for testing and putting it between two circular clamps are also part .

exhaust gas analyzers

endress hauser gas analyzers

Resultado da Desperte o chef em você com os Jogos de Comida no Jogos 360! Prepare pratos requintados dignos de restaurantes estrelados ou refeições simples .

burst strength test corrugated|5 ply corrugated box burst